Types of PLC Programming languages?

Introduction: Programmable Logic Controllers (PLCs) are the backbone of industrial automation, enabling the control and monitoring of machinery and processes. PLCs use specialized programming languages to facilitate communication between human operators and the machines they oversee. In this blog, we will delve into the types of programming languages commonly used in PLCs, shedding light on their unique characteristics and applications.

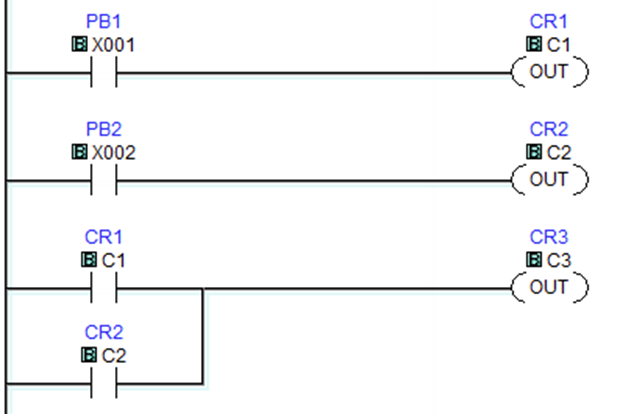

- Ladder Logic (LD):

Ladder Logic is one of the most widely used programming languages in PLCs. Its graphical representation resembles electrical relay logic diagrams, making it intuitive for engineers with a background in electrical control systems. Ladder Logic is ideal for representing discrete logic operations, making it well-suited for applications where the sequence of events is crucial.

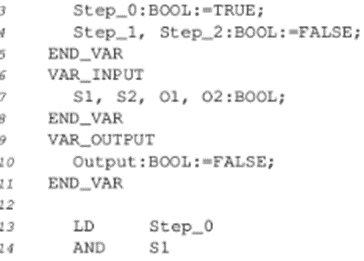

- Structured Text (ST):

For those familiar with high-level programming languages like C or Pascal, Structured Text provides a familiar syntax. This text-based language is powerful and versatile, allowing for complex mathematical calculations and data manipulation. Structured Text is commonly used in applications that require advanced algorithms and mathematical operations.

- Function Block Diagram (FBD):

Function Block Diagram is a graphical programming language that represents functions and their interconnections as blocks. Each block encapsulates a specific function, and these blocks are interconnected to create a program. FBD is advantageous for modular programming, facilitating the reuse of specific functions in different parts of the control system.

- Sequential Function Chart (SFC):

SFC is particularly suitable for applications involving complex sequences of operations. It uses a series of interconnected steps, transitions, and actions to represent the sequential nature of a process. SFC is excellent for applications where a step-by-step approach to control is required, such as batch processing or manufacturing.

- Instruction List (IL):

Instruction List is a low-level, text-based programming language that closely resembles assembly language. While less intuitive for beginners, IL provides a direct mapping to the processor's machine code, making it efficient for certain applications that require precise control over the hardware.

Conclusion: Understanding the diverse programming languages used in PLCs is crucial for engineers and programmers working in industrial automation. Each language has its strengths and is best suited for specific applications. As technology continues to evolve, so too will the programming languages employed in PLCs, ensuring that these essential devices remain at the forefront of industrial automation.

.webp)

0 Comments